6 Easy Facts About Mhs - Material Handling Supply Inc. Explained

Table of ContentsNot known Incorrect Statements About Mhs - Material Handling Supply Inc. Indicators on Mhs - Material Handling Supply Inc. You Need To KnowRumored Buzz on Mhs - Material Handling Supply Inc.The Facts About Mhs - Material Handling Supply Inc. UncoveredAll About Mhs - Material Handling Supply Inc.What Does Mhs - Material Handling Supply Inc. Do?

This line is called the line of activity. forklift rental. If all-time low of this line goes beyond the stability triangular because a lots is too hefty or too expensive, or since the forklift is not on a level surface area it will topple. A vertical line prolonging from the facility of gravity of the vehicle-load combination have to stay inside the security triangle to avoid the forklift from tippingThis security triangle is made by linking the 2 front wheels and the pivot factor of the back axle. The other concept to comprehend is the forklifts center of gravity. Notice that the front and back sides of the stability triangular are high-lighted. When unloaded, the forklifts center of mass is best concerning here.

Heavier tons change the center of gravity ahead also additionally. Raising the lots also moves the center of mass onward. In order to avoid the lift from tipping, the mixed center of gravity of the load and the lift need to remain inside the stability triangle (at ground degree) in all times.

Things about Mhs - Material Handling Supply Inc.

If you have a balanced load, the load is not likely to influence the side-to-side facility of gravity. https://www.figma.com/file/FCBd6aHTDRFLA85FpKRsIO/Untitled?type=design&node-id=0%3A1&mode=design&t=IJckpFk7ys2cuE5q-1. If you drive on a sloped surface, your center of gravity might pass exterior of the security triangle and the lift could tip. Every forklift has a recognition plate that lists essential info concerning the vehicle

To make sure that the center of gravity of your forklift stays inside the stability triangle, don't try to raise anything much heavier than the recognition plate permits. Regardless of just how busy you are, you must examine your forklift before using it. If you do discover something that might impact the safety and security of the lorry you have to report it right away.

Comply with the operators handbooks supplied by the devices maker. These handbooks define the secure procedure and upkeep of forklifts. Keep in mind, the operator is liable for the secure operation of the forklift. Do a pre-operation examination prior to every shift. If the forklift is used all the time, evaluate it either prior to each change or after each shift.

Unknown Facts About Mhs - Material Handling Supply Inc.

It is completed in two components: the walk-around inspection, and, the seated assessment. OSHA does not require paperwork of a day-to-day evaluation. However it's an excellent idea to have a checklist to make certain you do not miss any type of actions. These lists can additionally be conserved as a component of the maintenance document.

Inspect the problem of the tires. If the forklift is an exterior forklift with pneumatically-driven tires, check the air pressure and try to find too much endure the tires. A tire with reduced air stress could cause the lift to tip when a load is increased. Might a tire failing.

Excitement About Mhs - Material Handling Supply Inc.

Inspect the engine for any indicators of wear, loose connections, or leakages. Look for cracks or defects in the forks, backrest, mast, and above guard. Check the recognition plate to make sure it is undamaged and clear.

Constantly start the engine while seated in the operator's positionnever while standing along with the forklift. Inspect all evaluates and warning lights, and the battery or gas degree. Lift and decrease the forks, and tilt the pole.

The Definitive Guide for Mhs - Material Handling Supply Inc.

Inspect the brakes by dispiriting the brake pedal. Examine the steering. Move the forklift onward a couple of feet.

Look for sparks Our site or flames coming out of the exhaust system. If you discover anything incorrect with the forklift during the walk-around or seated inspection, do not operate it up until it has been repaired.

The Single Strategy To Use For Mhs - Material Handling Supply Inc.

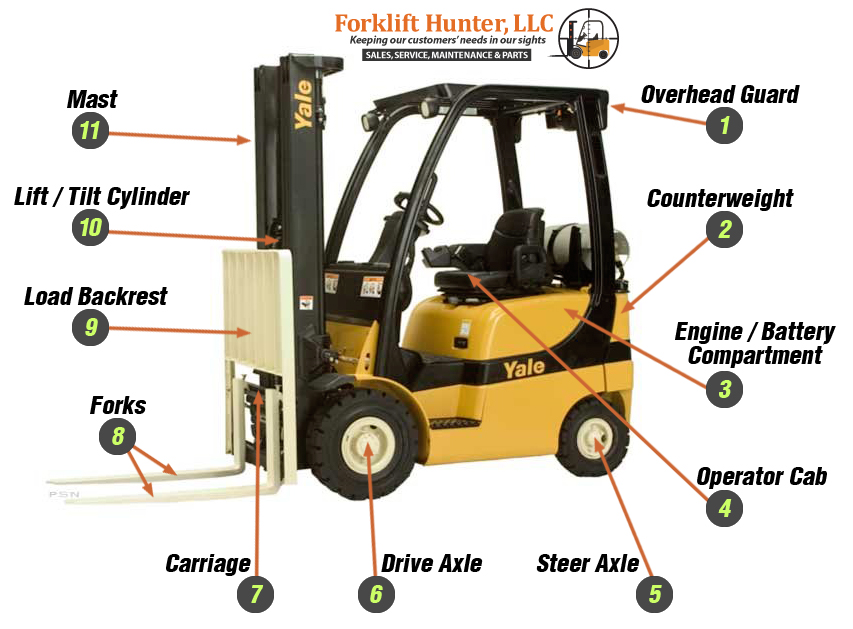

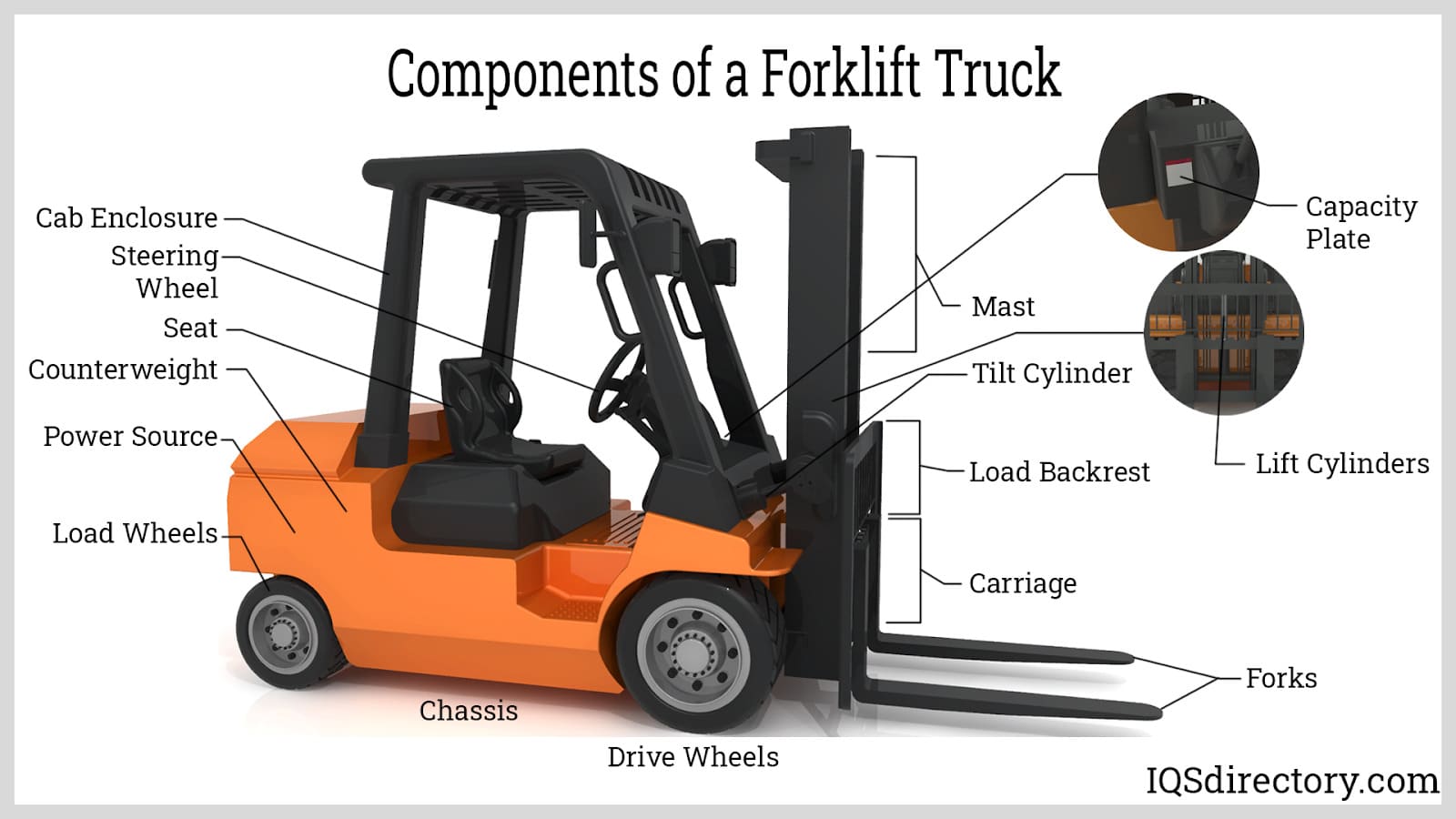

Forklifts have lots of moving parts and items that permit the forklift to run appropriately. Comprehending the terminology of the components and makeup of a forklift is essential for efficient communication with others while on duty - https://peatix.com/user/21999610/view. Below are several of the basic attributes and components that compose the makeup of a forklift vehicle

For the majority of forklifts, the pole is made towards the front of a forklift and directly in the forklift operator's line of sight. Forklift masts come with numerous sections that boost or reduced the forklift carriage in addition to the forks. These consist of:: 2 mast stages: Three pole phases: Four mast areas When picking a forklift, it is essential to acquaint on your own with the different features and terms of a forklift pole: the mast's lift height, the free lift elevation and the prolonged height and the lowered elevation.